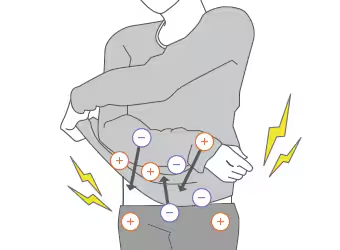

In our daily lives, static electricity is a common phenomenon that we often encounter. For instance, when putting on or taking off clothes, we might experience a small, sharp pain caused by electrostatic discharge (ESD). This sensation is particularly noticeable during the cold, dry winter months, prompting us to wonder: How does humidity affect ESD?

What are Humidity and Relative Humidity?

Air humidity refers to the amount of water vapor present in the air. Relative Humidity (RH) is the most commonly used measure of humidity and is expressed as a percentage (%). It represents the amount of water vapor in the air relative to the maximum amount of water vapor the air can hold at a given temperature.

What is ESD and how does it occur?

From the ESD Basic Knowledge, we know that ESD, aka Electrostatic Discharge, is the sudden current flow between objects with different charges. Common sources of ESD include:

- Friction

- Contact

- Separation

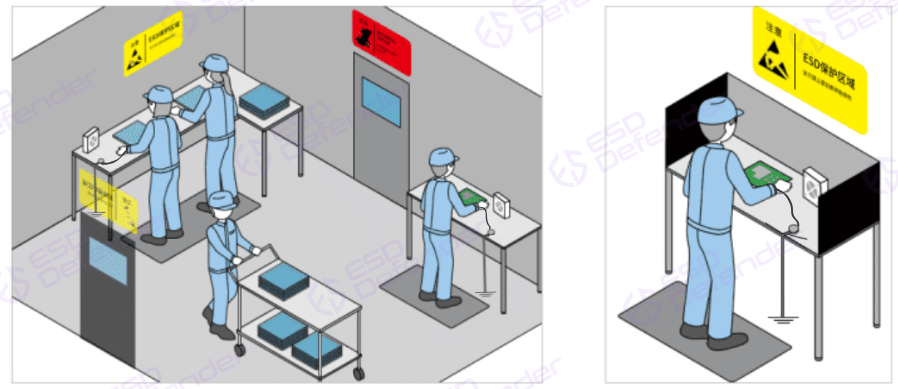

In the electronics manufacturing industry, routine activities such as workers walking across floors, the movement of conveyor belts, and the friction and contact between carts and other objects can generate significant amounts of static charge. When this accumulated static charge discharges, it can destroy ESD sensitive device like microchips, resistors, or circuit boards.

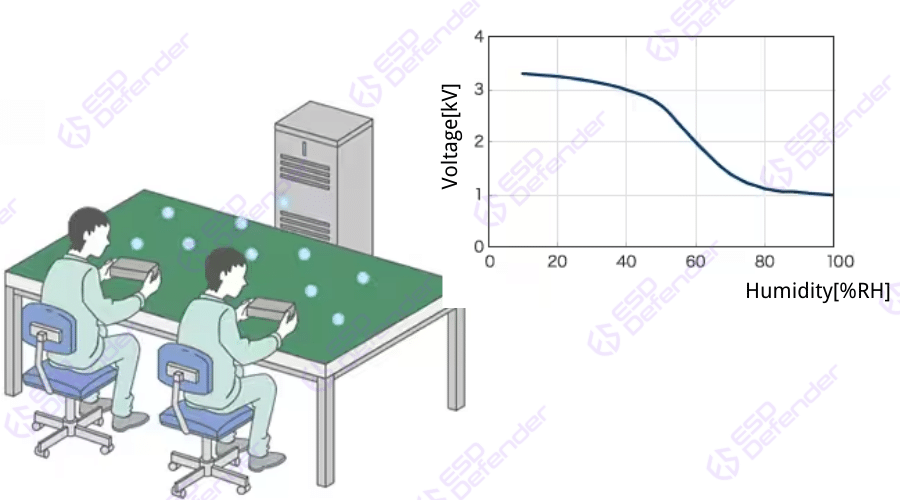

How does humidty affect ESD?

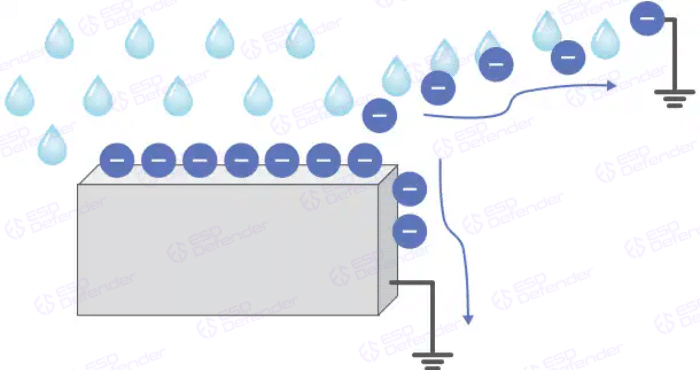

The amount of static charge accumulated on a person or object is influenced by factors such as material properties, surface conditions, contact and separation processes, and humidity. Humidity, the amount of water vapor in the air, directly affects the buildup and discharge of static electricity. At higher humidity levels, moisture in the air forms a thin layer of water molecules on surfaces, enhancing conductivity. This helps neutralize static charges, preventing them from reaching dangerous levels. Conversely, in dry conditions, surfaces become more insulating, promoting static charge accumulation.

Optimal Humidity Levels for ESD Control

So, is higher humidity always better? Of course not. While higher humidity can effectively reduce the risk of electrostatic discharge (ESD), excessively high humidity may lead to other issues, such as condensation, corrosion, and mold growth. Therefore, in an Electrostatic Protected Area (EPA), humidity control needs to strike a balance.

Maintaining relative humidity (RH) between 40% and 60% is widely recommended in ESD-protected areas (EPAs). Within this range:

- Static charges dissipate effectively without causing corrosion or other moisture-related issues.

- The risk of ESD damage to sensitive components is minimized.

- Worker comfort and productivity are maintained.

For drier environment, air humidifiers can be used to achieve the ideal humidity level, thereby reducing the likelihood of static electricity buildup. However, it is important to note that maintaining proper humidity alone cannot completely eliminate the generation of static charges. Therefore, it should not be considered a substitute for other essential ESD control measures. Operators must still wear wrist straps and ESD-safe footwear, and workbench and floors must be properly grounded. These measures provide a controlled path for static charges to flow safely to the ground, reducing ESD events effectively.

Can Humidifiers Eliminate ESD?

In ESD-sensitive areas like SMT (Surface Mount Technology) workshops, humidifiers are often used to control humidity and reduce electrostatic discharge risks. Some people might wonder: Can a humidifier alone eliminate ESD threats? The answer is NO. Here’s why.

The Limits of Humidifiers

While humidifiers address one factor—air dryness—they cannot fully prevent ESD. Static charges are fundamentally generated through physical processes:

- Friction: Movement between materials (e.g., conveyor belts, human activity).

- Contact and Separation: When two surfaces touch and separate (e.g., peeling tape, handling components).

Even in a humid environment, these actions can still create charges. For example, workers wearing synthetic clothing or improperly grounded equipment can generate static, regardless of humidity levels.

A Holistic Approach Is Key

To minimize ESD risks effectively, rely on layered measures:

- Humidity Control: Keep relative humidity between 40-60% (ideal for reducing static buildup).

- Grounding Systems: Ensure all personnel, workstations, and equipment are properly grounded.

- ESD-Safe Materials: Use anti-static flooring, ionizers, and static-dissipative tools.

- Training: Educate staff on ESD-safe practices (e.g., avoiding rapid movements, using wrist straps).